Above mentioned parts especially valves require periodic inspection and maintenance.

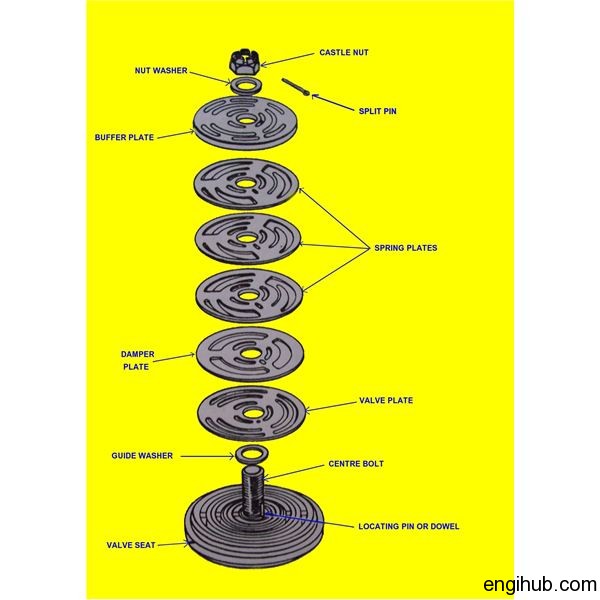

Here you will find important information about plate type suction and discharge valves. These types of valves are used in Kirloskar Pneumatic and Chicago Pneumatic Air Compressors.

Ingersoll Rand also uses plate type valve in their compressor but in a square shape. The Maintainance is almost the same for any type of compressor.

The below information will definitely help you in servicing of suction and discharge valves of the reciprocating air compressor.

How to dismantle the valves

To avoid damage to the valves and inner dowel pins, it is suggested to use a simple fixture for dismantling and assembling valves.

These fixtures are supplied by the compressor manufacturers on a chargeable basis or you can manufacture them at your engineering unit also.

A detailed drawing is always available in an instruction manual. Use proper size spanner for opening and tightening. Never hold the valve directly in a vice and do not hammer on the spanner when loosening or tightening the castle nut.

How to clean the valve

Examine all the parts thoroughly after dismantling the valve. Remove carbon formation with help of Trichloroethylene or diesel and light scraping paper or brush.

Don’t scratch the valve plate or seat while cleaning. Completely dry out the valves before installing them on a compressor.

Never use cotton waste to clean the internal parts of the valve, use only cloth for drying out. Dry air can also be used for this purpose.

Inspection and Reconditioning of valve

When the valve plate, damper plate, and spring plate shows sign of wear, it is imperative to replace these parts, even if no breakage has occurred.

Maximum wear of about 10 % of the total thickness of the valve plate is allowed. For the highest efficiency of the valve, it is important that the seat face is flat and free from any traces of wear. This prevents valve leakage.

If any damage to the seat is observed, it is recommended to replace the same. Due to the presence of dowel pins, re-machining or lapping cannot be carried out. It is also suggested to use a new valve plate with a new valve seat.

Reassembly and Installation of valve

A) Carry out valve assembly in the required sequence. Use fixture for proper tightening of valve nut. Check valve plate for free movement.

The best sequence is first valve seat then washer then valve plate then damper plate then spring plate. Keep one washer then valve keeper and tight this assembly with the nut. (Refer to diagram of the instruction manual)

B) The hollow side of the thin part in the center of the valve plate must be placed upward facing, the valve keeper.

C) Suction valves are equipped with an unloader, the clearance between the valve plate and unloader lifter as well as the clearance between the unloading piston and lifter must be checked.

D) Test the valve for leakage and ensure it is made dry after testing. Use an air pressure instrument for testing purposes. Never use petrol, diesel, or kerosene for inspection.

E) Valve cover nuts have to be tightened with specific torque by a torque wrench.

This is all about the proper maintenance of the suction and discharge valves of an air compressor. Hope you like it.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.