In automobile engineering, it is most important to supply the proper air-fuel ratio in the inlet manifold of the internal combustion engine. A good Carburetor will do this for your engine.

The internal combustion engine has a very low comparison ratio. It also uses highly volatile liquid fuels such as petrol, paraffin, etc. Hence the carburetion process is a must requirement.

The process of breaking up the fuel into minute particles and mixing it with air is known as carburetion.

In the carburetor, the fuel is completely broken into the minute particles, vaporized, and mixed with the air in a proper ratio.

The homogeneous mixture of fuel and air thus obtained is supplied to the engine cylinder.

Here I will like to share information on Simple Carburetor with you. For the other types of carburetors, you can read articles,

How to Break Fuel into Minute Particles

This device is used in petrol engines or similar liquid fuel engines. By means of which the fuel mixed with air is supplied into the induction manifold of the engine.

The carburetor controls the required quantity of fuel and breaks it up into minute globules. This afterward is mixed with the correct quantity of air.

The main purpose of a carburetor is to supply the required quantity of petrol and air mixture. The strength must be correct as per the requirement of load conditions of the engine.

The ratio should not be more than 20:1 and not less than 8:1. The ideal ratio is 15:1

Construction of Simple Carburetor

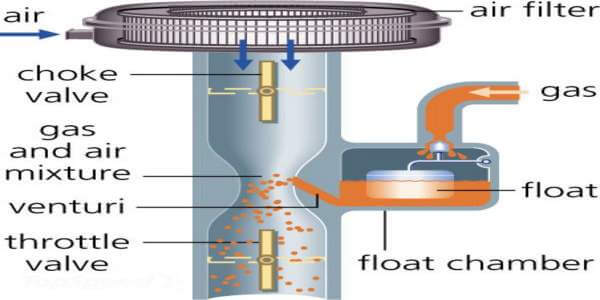

A simple carburetor consists of a venturi and a fuel jet located therein. For maintaining the level of fuel in the jet, a float chamber is usually required.

A throttle valve in the form of a flat circular metal disc mounted on a spindle. This is provided for controlling the flow of air-fuel mixture to the induction manifold.

A rotary type valve also can be used instead of a disc type.

The level of fuel is just kept slightly below the top of the jet to prevent leakage when not in operation.

Normally 1.5 mm difference is kept between the top of the jet and the surface of the fuel in the float chamber.

Working of Simple Carburetor

A needle valve controls the passage of fuel from the fuel pump when the air begins to flow past the jet; a low-pressure zone is created in the venture because of the increased velocity of air.

The fuel begins to rise because of the difference in the air pressure on the fuel which is equal to the pressure of the atmosphere and on the fuel in the jet at the venturi and issue out from the jet in the form of a fine spray.

Minute petrol particles present a large surface area being exposed to the air stream.

The fuel is not completely vaporized in a carburetor and some globules of fuel still enter the induction manifold. Those are vaporized during the compression stroke in an engine cylinder.

A check valve controls the flow of air into the carburetor. The gas-tight connection is provided between the carburetor and the induction manifold.

When two concentric venturi are provided, the discharge end of the inner venturi is called the “Primary Venturi”. This lies just at the throat of the main venturi.

A higher velocity of air which aids in the atomization of the fuel is obtained at the throat of the primary venturi. As there is a lower pressure compared to the main venturi.

The main advantages of multiple venturi are, that these keep the fuel away from the carburetor walls. Hence obtaining a considerable reduction in fuel consumption.

The Simple Carburetor may be of the following three types

01) Updraft Type: In this, the air enters the carburetor at the bottom and leaves at the top.

02) Downdraft Type: In this, air enters the carburetor at the top and leaves at the bottom. This is used in most passenger cars.

Because it can be installed at a higher level in the engine. Hence making it more accessible for the purpose of inspection and repair.

03) Side draft Type: It has more width and the mounting of the oil bath air filter is clumsy.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

- Internal Combustion Engines

- Internal Combustion Engine Fundamentals

- Engineering Fundamentals of the Internal

- A Textbook of Internal Combustion Engines

If you like the post, share it with your friends and also on social sites.