Lubrication is the prime need for all moving parts. It reduces frictional losses and increases the efficiency of the machine.

In an oil-free air compressor, lubrication is required in running gear only. Running gear is an assembly of various parts like crankshaft, connecting rod, main bearing, etc.

Non-Lubricated compressors are fitted with cylinders that don’t require lubrication. The Teflon Piston Rings take care of lubrication in an oil-free air compressor.

Here I will like to share the information on how to carry out lubrication in reciprocating air compressors so you can better maintain your valuable engineering utility.

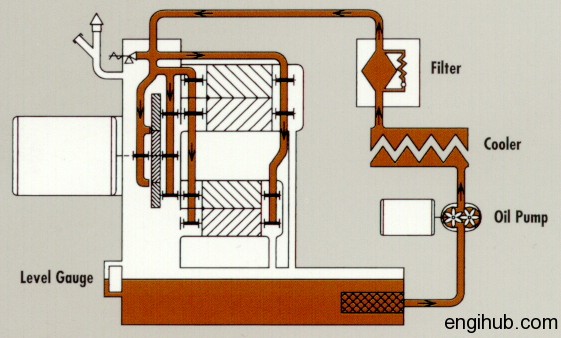

In this type of lubrication system, a strainer, oil pump, and tubes are used to lubricate the moving parts. Basically, this lube oil system is used in reciprocating air compressors manufactured by Chicago Pneumatics, Ingersoll Rand, Kirloskar Pneumatics

How Oil Lubrication Carried Out in Chicago Pneumatics Air Compressor

An oil pump is used to pump up and increase oil pressure from the crankcase sump.

This positive displacement rotary pump is driven by the crankshaft through an oil pump drive shaft.

The oil pump draws oil from the frame sump through a fine perforated sheet strainer.

Oil pump discharge is taken to the cartridge paper-type oil filter. The filtered oil through the copper pipes is led to each main bearings, drive end, and non-drive end.

The oil from the main journals of the crankshaft flows to crank pins through the rifle drilling holes. And also from crank pins to small end pins through rifle drilled hole in connecting rod.

Facing the belt wheel, having a clockwise direction of rotation, the left-hand cross slide that is fitted towards the first stage or low-pressure stage is pressure lubricated.

A copper tube connection is taken through a tee connection in the main oil line and connected to a choke.

This is fitted on the top face side of the cross slide. The lubrication oil through the choke flows from the center of the cross slide to the top of the crosshead.

The cross slide and crosshead fitted towards the second stage or high-pressure stage are splashes lubricated in the case of HX models.

Since the direction of rotation is clockwise when viewed facing the belt wheel, the splashed oil from the second stage connecting rod bearing falls on the top of the cross slide.

The top of the cross slide is specially built with an all-around small dam in which the splashed oil accumulates and through the drilled hole, falls on top of the cross head for lubrication.

In the case of the HN Model, which has a higher capacity than the HX Model, the second stage cross head is lubricated through the choke with a separate lube line.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.