Purchasing a compressor from Atlas Copco, ELGI, Ingersoll Rand, Kirloskar, Chicago Pneumatic, etc. will not guarantee trouble-free operation.

All Engineers in an engineering manufacturing unit must have overall knowledge about the efficient running of the utilities.

So, the below points will better help you obtain the best performance of the compressor.

Today there are many educational courses offered by various institutes about piping but it requires money to invest.

If you don’t want to be an Expert Piping Engineer but to know-how should be the discharge pipeline required for an air compressor then just go through the below points.

I am confident if you follow the below points while designing, you can design a good discharge pipeline for your air compressor.

So, here are the 10 Important Points to follow for Designing of Discharge Pipe Line

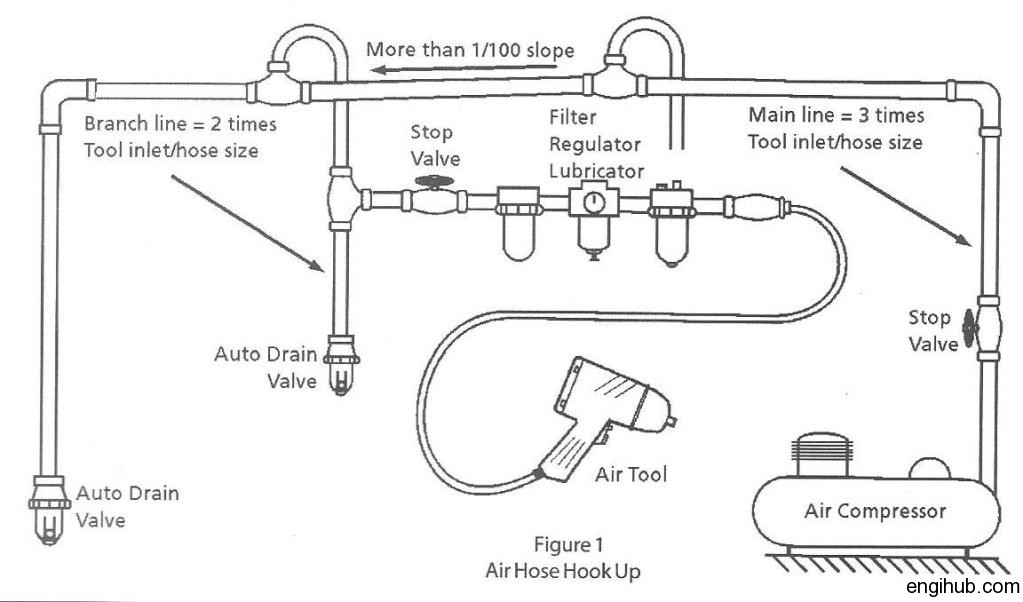

01) Discharge Pipeline should be the same size as shown on the General Arrangement. It should have few turns as possible.

02) It should connect as directly as possible to the middle or lower part of the receiver.

03) It is advisable to design a discharge pipeline system to prevent Resonance and excessive pulsations.

04) The discharge pipeline must be supported at a frequent distance.

05) In order to avoid stress, the discharge pipeline system must be free from expansion.

06) It is essential that the pipe size should be sized to prevent excessive pressure drop to avoid power loss.

07) It is good practice to increase the pipe by one size for every 100 feet length from air compressor discharge.

08) Use long radius elbows to reduce air friction. Hence it is suggested to make all piping as direct and short as possible.

09) Never place a Shut-off valve in the discharge line between the receiver and the compressor. Unless a Safety Valve is inserted between the valve and the compressor.

10) Place a Shut-off valve in each discharge pipeline near cylinder discharge. This should be done if two or more air compressors are connected to the same system.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.