The knowledge of the Classification of the air compressor will help you to choose the best compressor to fulfill your need.

The engineering unit may be small or big, everyone uses an air compressor to perform various tasks as per the requirement.

For different kinds of requirements, different types of compressors have to be used.

The selection of compressor depends upon various factors, such as capacity, pressure, cost, running cost, maintenance cost, availability of spares, availability of service engineer, etc.

If you know the classification of compressors properly, it will help you to select a better one.

Here I am going to share some important information on the classification of an air compressor with you, hope you like it.

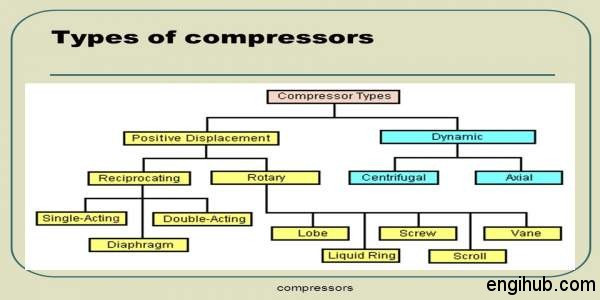

So, Here is the Classification of Air compressors that Comes

According to the number of stages

(b) Two-stage

(c) Multistage

According to moving parts

(b) Rotary

(c) Centrifugal

According to duty

(b) Medium pressure

(c) High pressure

According to the number of power cylinders

(b) Double cylinder

(c) Multicylinder

According to the method of cooling

According to the number of cylinders

(b) Duplex

(c) Triplex

According to the nature of the installation

(b) Semi-fixed

(c) Fixed

According to an application

(a) Rock drill compressor

(b) Pneumatic hand tool compressor

(c) Road building compressor

(d) Mining prospecting compressor

(e) Sandblasting compressor

(f) Spray painting compressor

According to power drives

(b) Belt drive

(c) Chain drive

According to the principle of operations

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.