The chilling effect can be produced by vapor-compression or vapor absorption cycle.

In vapor compression engineering, the compressor is used for the chilling effect.

Whereas this compressor is replaced with a solution circuit and a pump, and this function is commonly referred to as a thermal compressor, thermochemical compressor, or a chemical compressor in the absorption cycle.

How are Vapor Absorption Chilling Process is classified?

There are two major classes of absorption equipment, direct-fired and indirect-fired.

Direct-fired equipment has an integral burner as the heat source, while indirect-fired equipment uses hot water or steam as the heat source for chilling.

These are further classified as single effect, double effect, and multiple (Triple) effects.

Why use Absorption Chillers?

Absorption chillers’ thermodynamic cycle is driven by the heat source; this heat is usually delivered to the chiller via steam, hot water, or combustion.

Compared to electrically powered chillers, they have very low electrical power requirements – very rarely above 15 kW combined consumption for both the solution pump and the refrigerant pump.

However, their heat input requirements are large, and their COPs are often 0.5 (single-effect) to 1.0 (double-effect).

For the same tonnage chilling capacity, they require much larger cooling towers than vapor-compression chillers.

However, absorption chillers, from an energy-efficiency point of view, excel where cheap, high-grade heat or waste heat is readily available.

What is the Difference between Vapor Compression and the Vapor Absorption Cycle of Chilling?

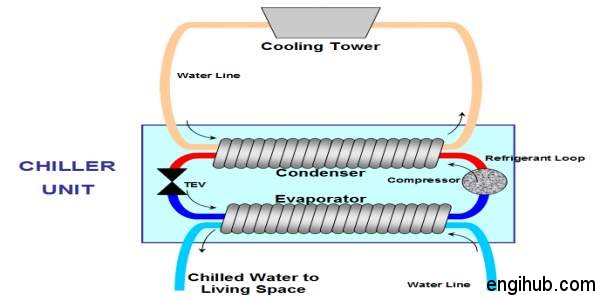

The basic difference between the vapor compression chillers and absorption chillers is that the vapor compression chiller uses an electric motor for operating a compressor used for raising the pressure of refrigerant vapors whereas an absorption chiller uses heat for compressing refrigerant vapors to high pressure.

The rejected heat from turbines, microturbines, and engines may be used for chilling.

In a vapor compression cycle, the low-pressure vapor is mechanically compressed.

In an absorption cycle, the low-pressure vapor is absorbed into a low-pressure solution, pumped to high pressure, and then heated to produce a high-pressure vapor.

How to select the pump for vapor absorption chilling?

Process pump specifications that are important to consider include the process flow, process pressure, pump material, rubber parts, mechanical shaft seal material, motor voltage, motor electrical class, motor IP rating, and pump rating.

Other important specifications include the internal water tank size and materials and full load amperage.

Which Solution Concentration levels should be used?

Weak Absorbent (dilute solution):

The solution has a low capacity for absorbing refrigerant.

The solution contains a high level of refrigerant in relation to the maximum that can be absorbed at a given temperature and proportionally lower levels of the absorbent.

Strong Absorbent:

The solution has a high capacity for absorbing refrigerant at a given reference temperature.

The solution contains a low level of refrigerant and proportionally high levels of absorbent.

What are the Advantages of Vapor Absorption Technology?

Environmentally friendly

Uses water as a refrigerant instead of ozone-depleting Chlorofluorocarbons.

Lower operating cost

Absorption chillers may have a lower operating cost than motor-driven vapor compression chillers.

Less Noise

Absorption chillers have lower noise and vibration generation than motor-driven vapor compression chillers.

Negligible power

Power is required for only small pumps.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details