There are some compressors used for medical purposes. Compressors can be used for refrigeration purposes also.

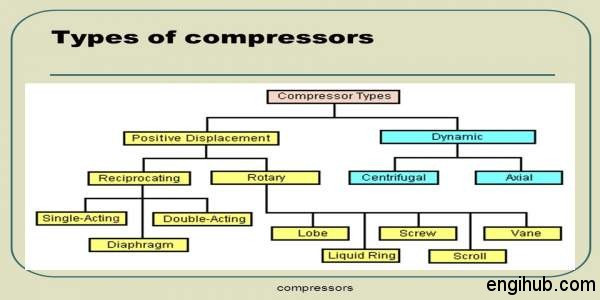

There are many more manufacturers to fulfill this demand. Over and all we know the compressor as per our requirement and technically these compressors are classified into only two types.

The classification is based on their construction and operation features.

So, the two main classifications of Air Compressor is

01) Positive Displacement Type.

02) Dynamic Type.

You will find details of each type below the description.

Positive Displacement Air Compressors

Positive displacement type compressors are those that mechanically displace a fixed volume of air into a reduced volume.

A compressor, when operated at a fixed speed, can deliver a constant volume. The discharge pressure is determined by the system load conditions.

If the consumption of air is more than discharge pressure falls below the cut-off pressure & the compressor works on load condition.

Hence these types of Air Compressor further classified as

Reciprocating Air Compressor

In this type compressed air is generated by the to & fro movement of a piston inside the cylinder (compression chamber). Hence each movement compresses a fixed quantity of free air at a specific pressure.

Single-stage or double-stage or multi-stage and single acting or double acting is the further classification.

A vertical type air compressor is used for the application of compressed air ranging from 50 to 150 CFM.

A horizontal balance type compressor is most suitable for applications ranging from 200 to 5000 CFM.

Rotary Air Compressor

In this type, the air is compressed by two rotating or intermeshing rotors. According to the type of construction Rotary Compressor can be further classified as

(a) Rotary Screw Compressor

(b) Rotary Vane compressor.

(a) Rotary Screw Compressor

Air is compressed between two rotating screws (male & female screws) and casing. So, the compression took place by gradually reducing the space between these two parts.

(b) Rotary Vane Compressor

Air is compressed between the casing & rotating rotor with the help of a movable rotor blade. This type can be further classified as a single stage or double stage rotary air compressor.

Dynamic Air Compressors

The dynamic type compressors mechanically impart velocity to the air. The impellers rotating at a high speed, in an enclosed casing, produce this action.

The air is forced into a progressively reduced volume. The volumetric flow will vary inversely with the differential pressure across the compressor.

This type of compressor is further classified as

(a) Centrifugal Air Compressor

(b) Axial Flow Air Compressor

(c) Roots Blower Compressor.

Centrifugal Air Compressor

In a centrifugal air compressor, an impeller is mounted on a shaft and positioned within the housing. It is consisting of an inlet duct, a volute, and also a diffuser.

The velocity of the air can be imparted by the high-speed rotation of the impeller. Hence the diffuser surrounds the impeller and acts to convert the kinetic energy of air into potential energy at a higher-pressure level.

Axial Flow Air Compressor

The axial flow type is essentially a large capacity, a high-speed machine with characteristics quite different from the centrifugal air compressor.

Each stage consists of two rows of blades, one row rotating & the next row of the blade is stationary.

The rotor blades impart velocity and pressure to the air as the motor turns, so, the velocity is converted to pressure in stationary blades.

Roots Blower Compressor

This type is generally called a blower. Hence the discharge air pressure obtained from this type of machine is very low.

In the single-stage, only one bar discharge pressure can be obtained and only 2.2 bar pressure is obtained from the double stage.

So, the discharge pressure is achieved by two rotors, which have separate, parallel axis and rotate in opposite directions.

Hence this is the example of a positive displacement compressor in a rotary-type air compressor.

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.