Here I will share the information on screw air compressors with you because every engineering plant requires compressed air to perform various operations.

To avoid various faults occurring during working on an air compressor, you have to know the working principle of the screw compressor.

The working principle described here will apply to all screw air compressors manufactured by Atlas Copco, Ingersoll Rand, Chicago Pneumatics, ELGI, etc.

Some Details About Screw Compressor

As the name indicates, this type of compressor is driven by an electric motor or diesel engine.

The rotary compressor is a single-stage, oil-flooded, rotary screw compressor driven by an electric motor through a coupling.

Nowadays two-stage, oil-free version is also available in the compressor industry. Teflon screws are used in such types.

A portable screw air compressor is mainly run by Diesel Engine.

Construction and Working of Screw Compressor

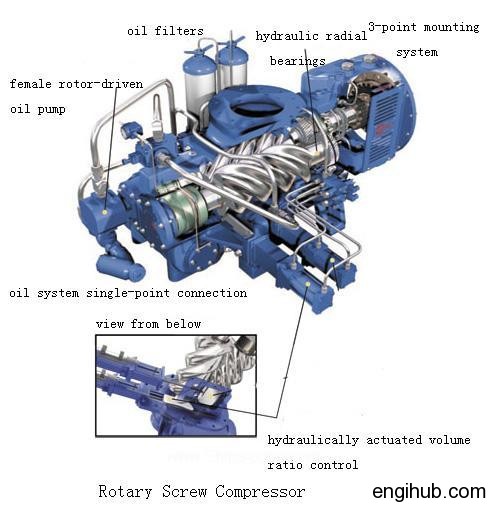

The compressor casing accommodates a pair of male and female helical rotors. These will be machined with the highest precision and mounted on rolling element bearings.

A pair of ball bearings and roller bearings are used on the drive and non-drive sides.

The male rotor has four helical lobes which mesh with six flutes of the female rotor. Hence the speed of the male rotor is 1.5 times higher than the female rotor.

The male rotor is driven by coupling through step-up gears. The male rotor lobes rotate into the female rotor flutes.

The air is sucked through the suction filter element trapped in the inner lobe spaces. So, it will smoothly compress until the lobe-flutes reach the outlet port.

Also Read: How to Govern Electric Screw Air Compressor

Pulsation-free air is delivered, due to continuous compression taking place in all the lobe-flute spaces.

The oil-injected through the lower gusset of the air compressor casing mixes with the indrawn air. It ensures an efficient sealing between the rotors and the casing.

This will also give an intensive cooling during the compression process.

Further Recommended Reading: How Air and Oil Flow In Screw Air Compressor

A Huge quantity of lubrication oil cools the compressed air; therefore intercoolers are not necessary for this type of compressor.

The oil, which lubricates the compressor, also seals the clearance spaces. In air-cooled models, the oil is cooled in the oil cooler by a separate fan motor. Whereas it is cooled by water, in water-cooled models.

Some more information on Screw Compressor

I hope the information above will help you understand the working of a screw compressor. To control various operations performed during working, many control valves are used. Like a minimum pressure valve, oil check valve, safety valve, and intake/butterfly valve.

Read: Function of Valves used in Electric Screw Air Compressor

Besides this information, you are suggested to read something more from below engineering books

So, Here you find the Best Engineering Resources for further details

To get the more details about the topic, I further recommended reading

If you like the post, share it with your friends and also on social sites.